Hazard Consequences

The purpose of the EN 17206 is to produce European specifications for the design, manufacture and installation of lifting and load bearing equipment within the entertainment industry.

The standard considers situations that give rise to danger, such as moving or holding scenery or equipment:

a) over persons and/or unprotected areas;

b) in areas with low light conditions, limited visibility, for example while using stage fog and other masking effects.

These situations apply not only during performances, but also during rehearsals, technical set-up, preparations, installations and other situations.

The document covers these hazards and suggests appropriate procedures to maintain safety.

Below you will find examples of different types of hazards and the consequences that are related to them. The illustrations will give you a visual explanation of the hazard consequences and provide guidance when you are allocating hazards in a risk assessment. The hazard type (which acts as the illustration title), hazard name and consequence will be listed under each illustration.

Click on one of the types of hazard below for guidance.

EXAMPLES OF MECHANICAL HAZARDS

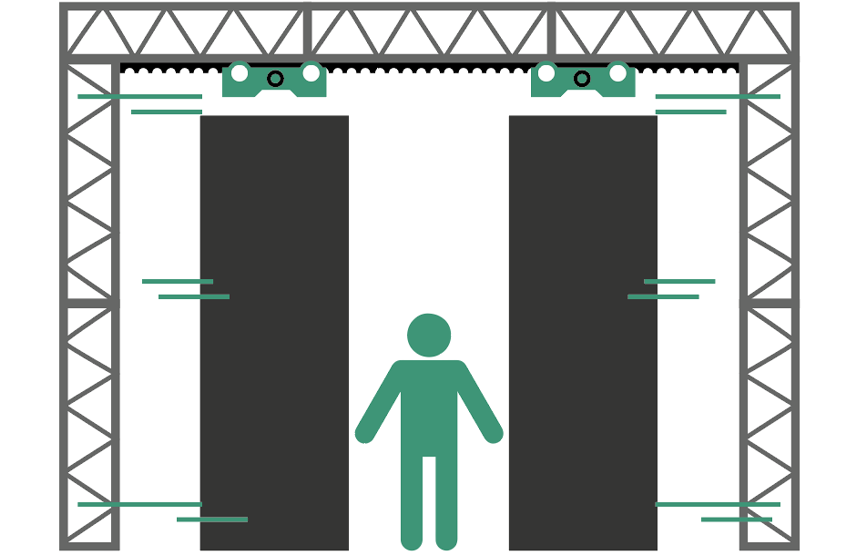

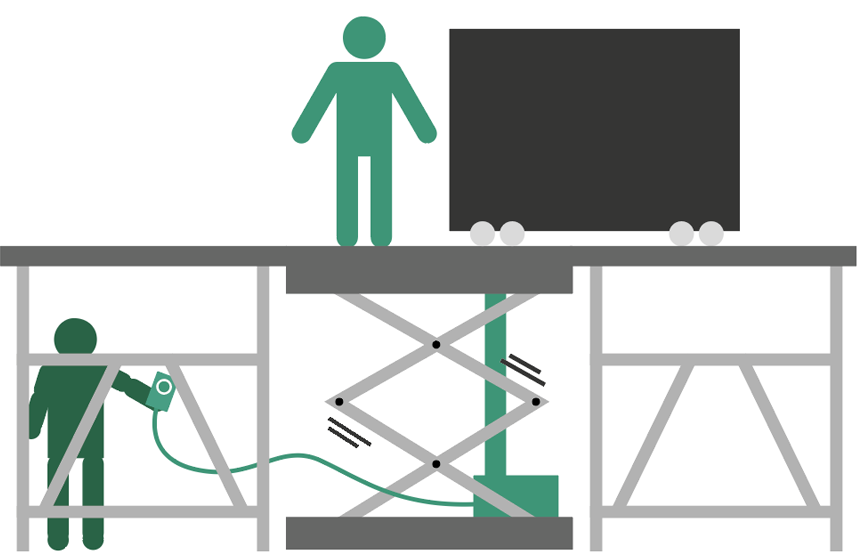

HAZARD: APPROACH OF A MOVING ELEMENT TO A FIXED PART

CONSEQUENCE: The potential consequences are crushing or impact, which can occur by being trapped between the machines moving parts or the load and a fixed structure, such as the wall or the floor. For example, people can be hit by lowered loads of the upper machinery or by horizontally tracked loads.

EXAMPLE – RISK ORIGIN: Incorrect installation, testing, use and maintenance

EXAMPLE – HAZARDOUS EVENT: Persons work on machinery which is being operated by a second person unaware of the first.

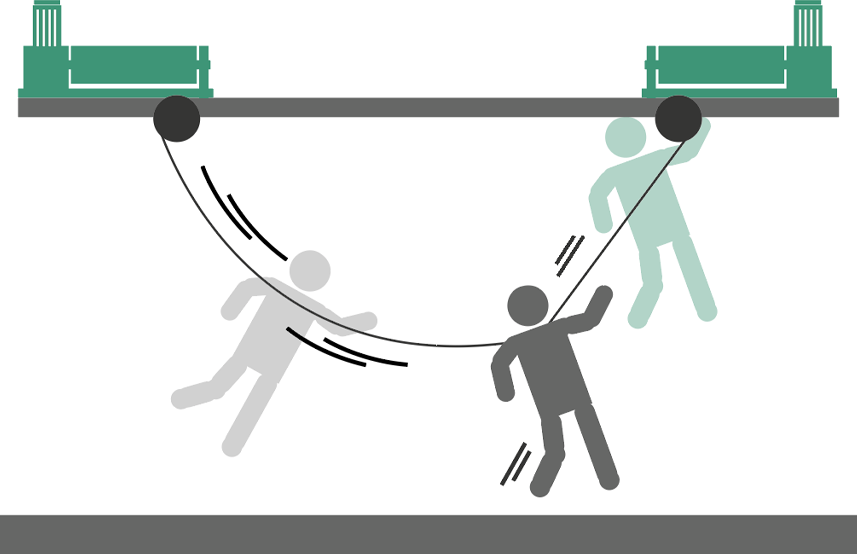

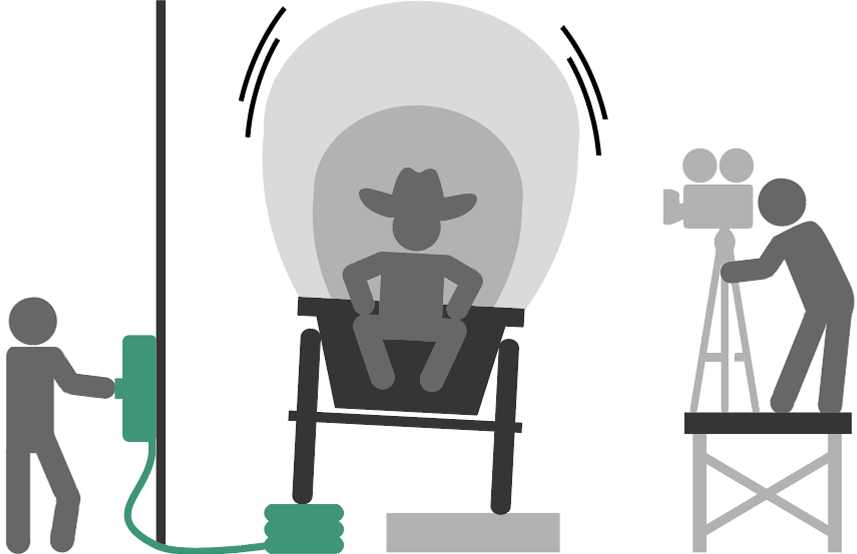

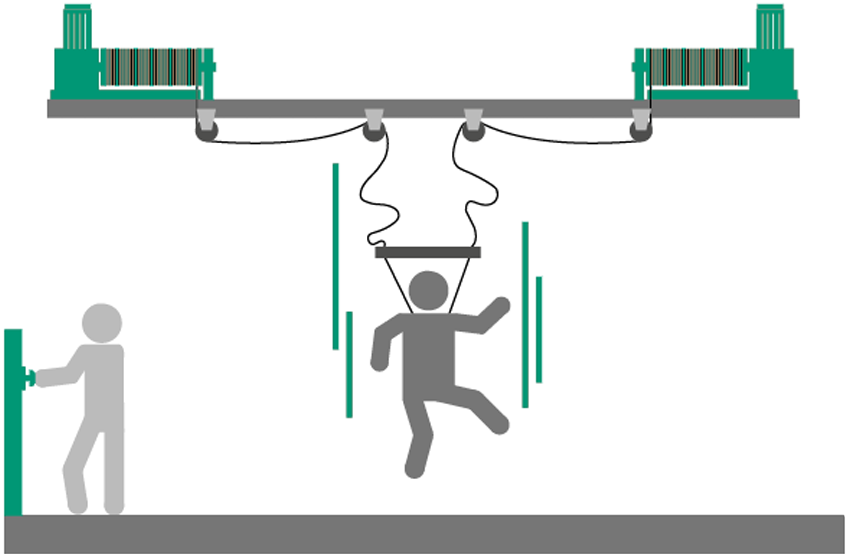

HAZARD: ACCELERATION / DECELERATION

CONSEQUENCE: Potential for impact, being thrown, run over, slipping, tripping or falling. For example, this can happen from a flying performer winch or a motorised wagon.

EXAMPLE – RISK ORIGIN: Uncontrolled movements

EXAMPLE – HAZARDOUS EVENT: Uncontrolled speeds

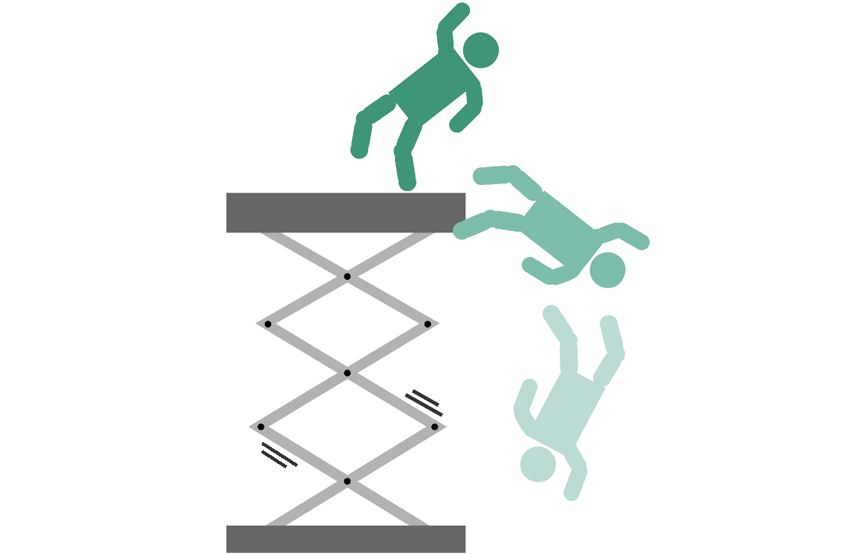

HAZARD: HEIGHT FROM THE GROUND

CONSEQUENCE: The potential consequences are crushing, impact, slipping, tripping or falling. For example, this can happen by being on a stage lift platform without handrails or accessing a rigging hoist for setting purposes.

EXAMPLE – RISK ORIGIN: Uncontrolled movements

EXAMPLE – HAZARDOUS EVENT: Unintentional drive start-up | Failure of drive system or locking device. Artists or crew standing on an elevated platform without handrails.

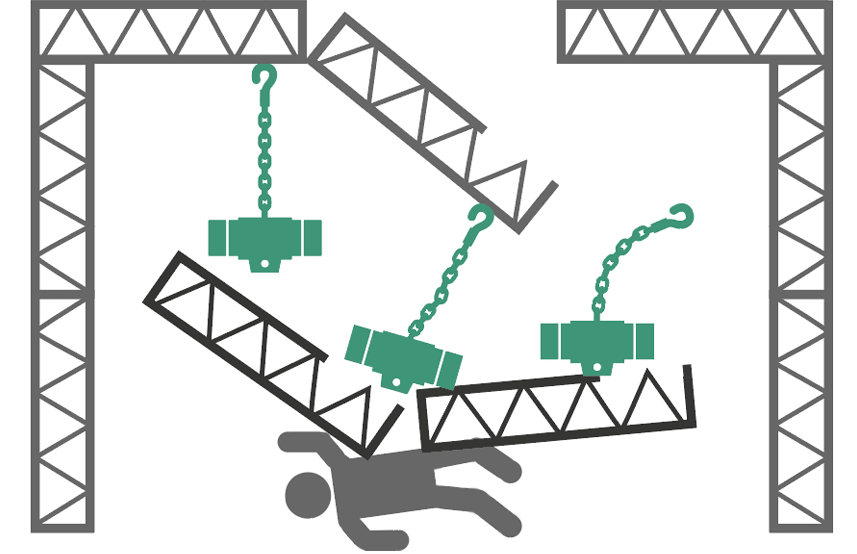

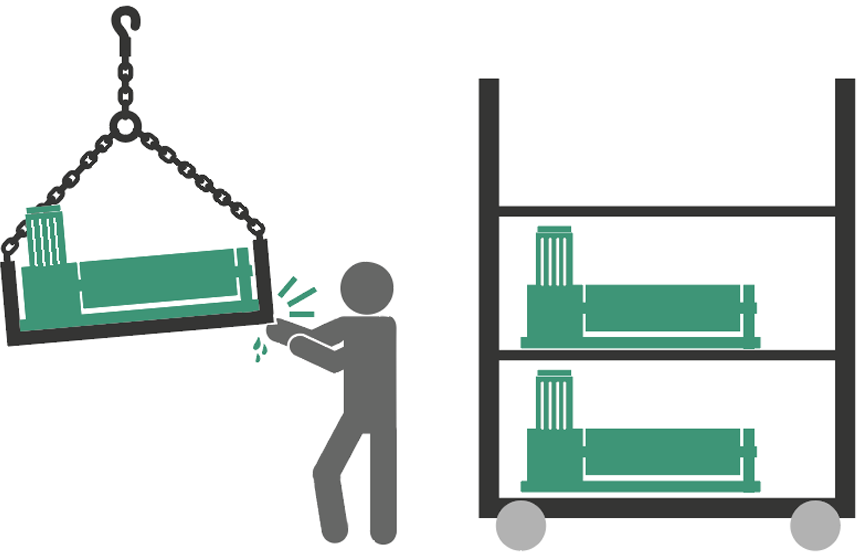

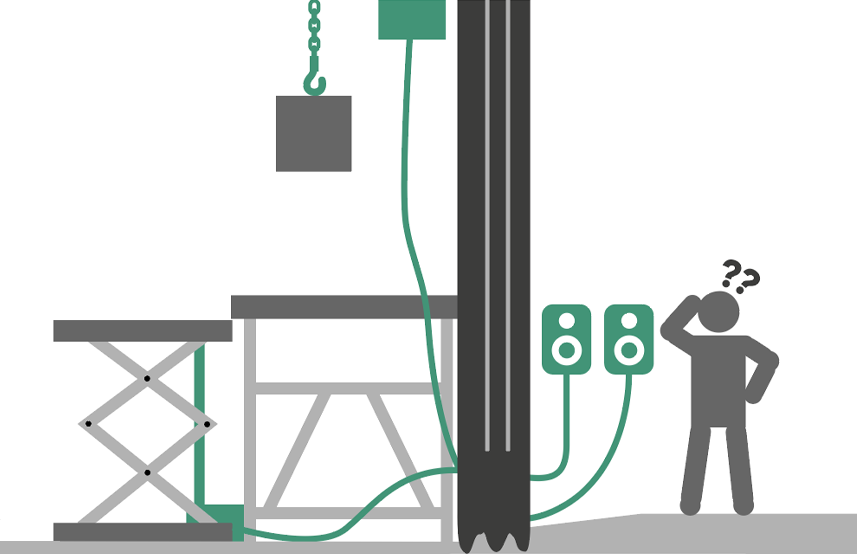

HAZARD: FALLING OBJECTS

CONSEQUENCE: The potential consequences are crushing or impact. For example, this could occur if a load fell from an overhead hoist, winch or rail/tracking system.

EXAMPLE – RISK ORIGIN: Incorrect design of machinery parts | Unsuitable design of load carrying devices and rope drums

EXAMPLE – HAZARDOUS EVENT: Incorrect dimensioning of structural elements and components. Chain hoist load suspensions, (hooks, plates or lugs) are not properly installed | Rope wear due to incorrectly dimensioned drum grooves

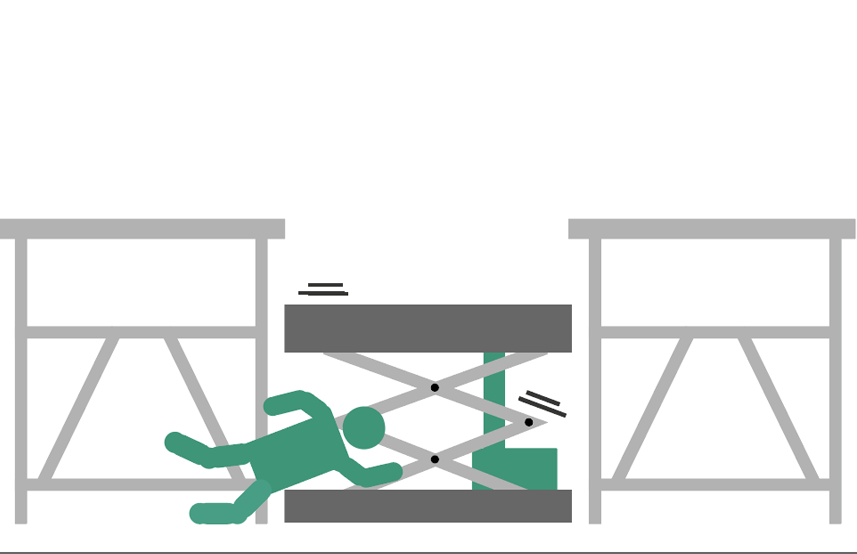

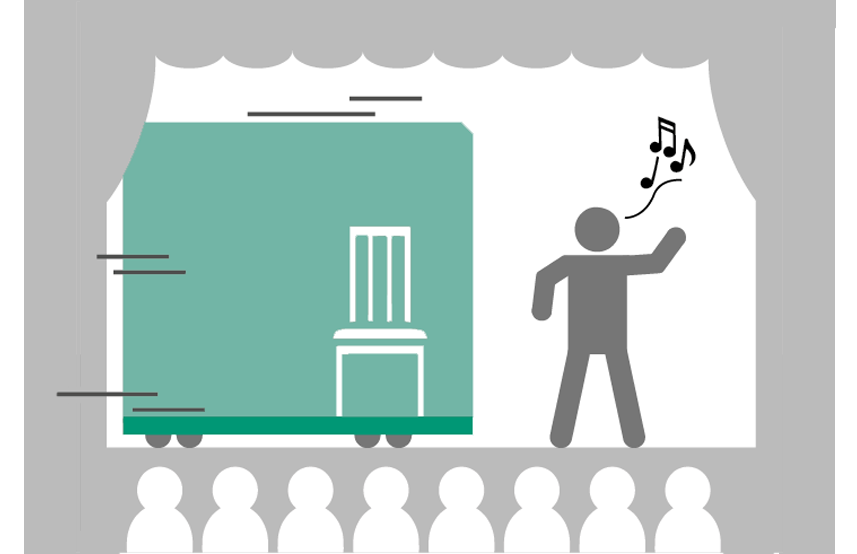

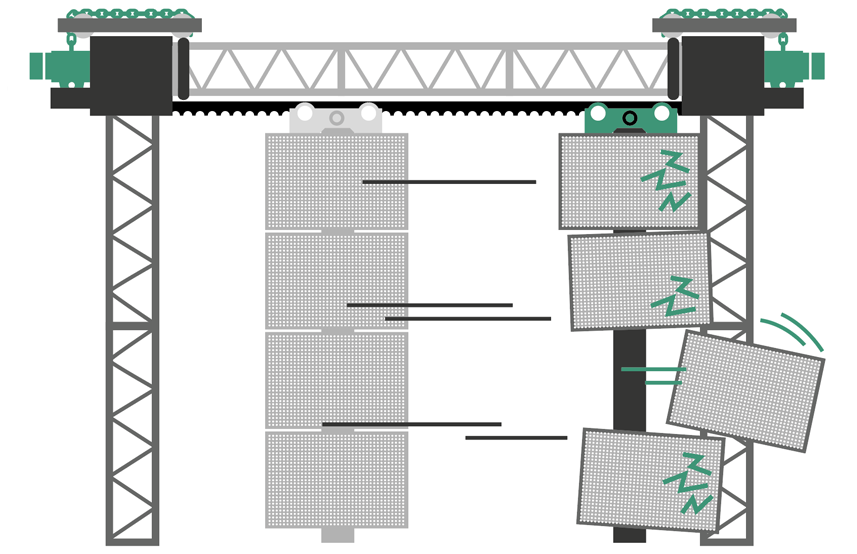

HAZARD: MOVING ELEMENTS

CONSEQUENCE: The potential consequences are crushing, friction, abrasion, impact, severing and drawing-in. For example, this can occur from tracking videos, telescopic masts, hydraulic rams or scissors.

EXAMPLE – RISK ORIGIN: Uncontrolled movements | Incorrect operation

EXAMPLE – HAZARDOUS EVENT: Exceeding specified travel limits | Tracking system travels to work position, persons stand in travel path

HAZARD: ANGULAR PARTS

CONSEQUENCE: Potential consequences include impact, crushing or shearing when a person hits a stationary part of the machinery.

NOTE: If the load impacts a person exposed to the risk, this is generally considered an “approach of a moving element to a fixed part”

EXAMPLE – RISK ORIGIN: Slipping, tripping or falling of persons (related to machinery)

EXAMPLE – HAZARDOUS EVENT: When lighting is low, understage area is not illuminated and performers hit angular parts.

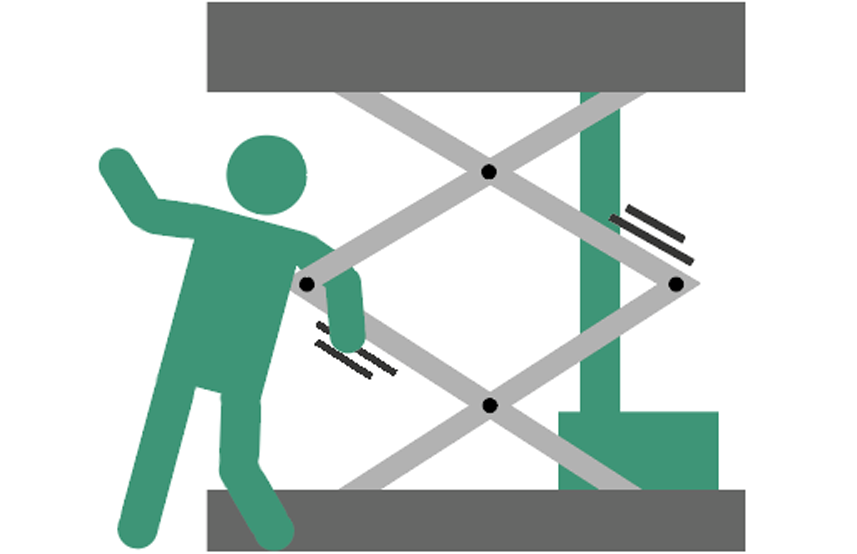

HAZARD: CUTTING PARTS

CONSEQUENCE: The potential consequences are crushing, friction, abrasion, impact, severing and drawing-in. For example, this can occur from tracking videos, telesPotential consequences are cutting or severing through contact with a cutting edge, such as the pantographs of a scissor lift.

EXAMPLE – RISK ORIGIN: Incorrect installation, testing, use and maintenance

EXAMPLE – HAZARDOUS EVENT: Persons standing in the danger zone, disregarding safety instructions, before safety measures or guards have been implemented.

HAZARD: ELASTIC ELEMENT

CONSEQUENCE: The consequences are crushing or impact when an elastic part is deformed and suddenly straightens or returns to its original dimension, or explodes when an airbag used for lifting fails.

EXAMPLE – RISK ORIGIN: Incorrect design of machinery parts

EXAMPLE – HAZARDOUS EVENT: Incorrect dimensioning of load-bearing elements and components

HAZARD: GRAVITY AND STABILITY

CONSEQUENCE: Potential consequences are crushing or trapping. For example, this can occur if a ground support system or a stage lift fails while a person is underneath.

EXAMPLE – RISK ORIGIN: Incorrect design of machinery parts

EXAMPLE – HAZARDOUS EVENT: Incorrect dimensioning of structural elements and components. Chain hoist load suspensions, (hooks, plates or lugs) are not properly installed.

HAZARD: INSTABILITY

CONSEQUENCE: Potential of being thrown, crushing or impact; for example, when a stage lift support, the stabilisers or the scissor supporting mechanism fails and the platform falls.

EXAMPLE – RISK ORIGIN: Incorrect loading, overloading, exceeding specified overturning moments

EXAMPLE – HAZARDOUS EVENT: Improper force or load transmission, stability calculations not carried out for load at failure.

HAZARD: HIGH PRESSURE

CONSEQUENCE: Potential consequences are injection, stabbing, impact or puncture, e.g. from a high pressure hydraulic system leak.

EXAMPLE – RISK ORIGIN: Incorrect installation, testing, use and maintenance

EXAMPLE – HAZARDOUS EVENT: Incorrect selection or installation of components

HAZARD: ROTATING ELEMENTS

CONSEQUENCE: Potential consequences are being thrown, impact, severing and being drawn-in. Some examples of this can occur from winch drums, gears or revolving rotating elements trapping pieces of fabric or limbs.

EXAMPLE – RISK ORIGIN: Drawing-in or trapping

EXAMPLE – HAZARDOUS EVENT: Hazards at winding devices and diverter pulleys. | Material or pieces of clothing get caught as ropes wound onto the drum

HAZARD: KINETIC ENERGY

CONSEQUENCE: Potential for impact, puncture or severing; for example, when a kinetic rope is used in a winch and it snaps, the whiplash can be very dangerous.

EXAMPLE – RISK ORIGIN: Incorrect loading, overloading, exceeding specified overturning moments

EXAMPLE – HAZARDOUS EVENT: Improper force or load transmission, stability calculations not carried out for load at failure.

HAZARD: MACHINERY MOBILITY

CONSEQUENCE: Potential consequences are being run over, impact and crushing. An example of this is when a large stage wagon is being manoeuvred on a small stage.

EXAMPLE – RISK ORIGIN: Incorrect operation

EXAMPLE – HAZARDOUS EVENT: Stage wagon travles to parked or show position, person(s) stand in travel path

HAZARD: SHARP EDGES

CONSEQUENCE: Potential consequences are severing, impact, shearing, stabbing and puncture. For example, this can occur when rough edges around the machinery enclosure might cut the skin to the touch.

EXAMPLE – RISK ORIGIN: Friction, abrasion, cutting or severing

EXAMPLE – HAZARDOUS EVENT: Contact with unfinished cast, partly machined or other sharp surfaces | Grabbing moving wire ropes

HAZARD: STORED ENERGY

CONSEQUENCE: Potential consequences are crushing, impact, puncture and suffocation when the stored energy is suddenly released. An example of this can occur when the valve of a system that is under pressure is broken off or a high pressure air hose breaks.

EXAMPLE – RISK ORIGIN: Incorrect design of machinery parts

EXAMPLE – HAZARDOUS EVENT: Gravitational energy released by a suspended load if primary or secondary brake is manually released

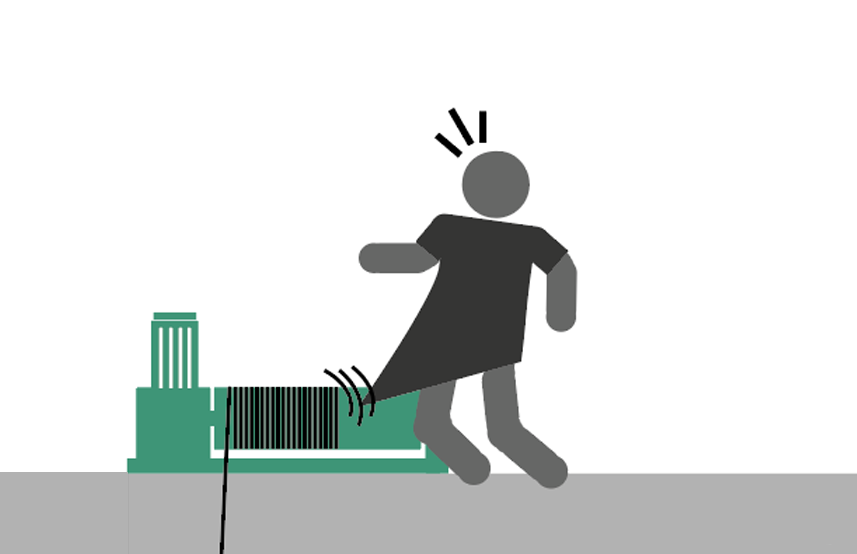

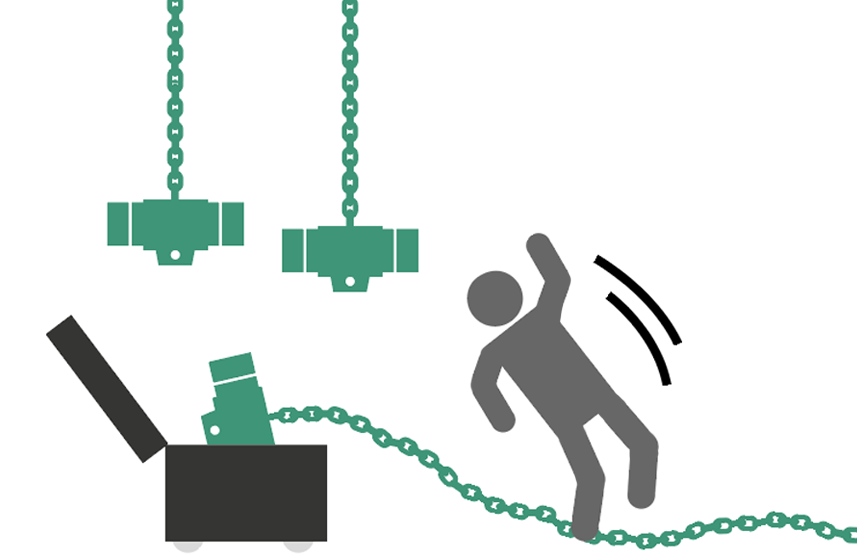

HAZARD: ROUGH, SLIPPERY SURFACE

CONSEQUENCE: The potential consequences are friction, abrasion, slipping, tripping and falling, and impact. For example, this can occur when the area around the machinery is very slippery or slippery machinery elements are left on the floor and the person exposed falls over the machinery hazard zone.

EXAMPLE – RISK ORIGIN: Slipping, tripping or falling of persons (related to machinery)

EXAMPLE – HAZARDOUS EVENT: Persons trip over tracking systems, or slippery surfaces, or load chains left on the venue’s floor.

EXAMPLES OF ELECTRICAL HAZARDS

HAZARD: ELECTROSTATIC PHENOMENA

CONSEQUENCE: Potential consequences are electric shock and related involuntary body movements; for example, this can occur when touching equipment that has an electric charge on it, which will momentary flow through your body when you touch a second piece of equipment.

EXAMPLE – RISK ORIGIN: Person(s) in contact with electrically charged elements or objects

EXAMPLE – HAZARDOUS EVENT: Momentary electric shock due to direct contact, e.g., due to faulty or inadequate insulation or lack of equipotential bonding. Falling from platforms.

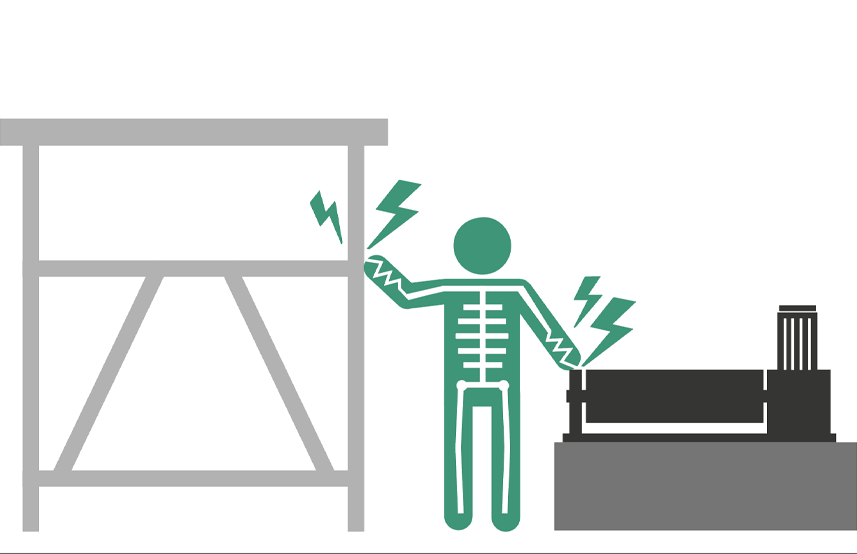

HAZARD: LIVE PARTS

CONSEQUENCE: Potential consequences are shock or electrocution; for example, when the connection or disconnection from the power supply cables to the connection strips, main switch or power disconnection switches.

EXAMPLE – RISK ORIGIN: Person(s) in contact with live parts (i.e. parts which are normally live)

EXAMPLE – HAZARDOUS EVENT: Electric shock due to direct contact

HAZARD: PARTS WHICH HAVE BECOME LIVE UNDER FAULTY CONDITIONS

CONSEQUENCE: Potential consequences are shock or electrocution; for example, when live mains that are not properly isolated touch metal enclosures or when metal parts are not properly earthed.

EXAMPLE – RISK ORIGIN: Person(s) in contact with parts which have become live under faulty conditions

EXAMPLE – HAZARDOUS EVENT: Electric shock due to indirect contact, e.g. due to faulty or inadequate insulation or lack of protective devices, MCB’s or RCD’s.

HAZARD: ELECTROMAGNETIC PHENOMENA

CONSEQUENCE: Potential consequences are impact, crushing or shearing caused by an unintentional start/stop or unintentional movement due to equipment with poor electromagnetic immunity.

EXAMPLE – RISK ORIGIN: Electromagnetic interferences

EXAMPLE – HAZARDOUS EVENT: Strong electromagnetic field generated by a frequency drive inverter. Motors or transformers not suitable for the application.

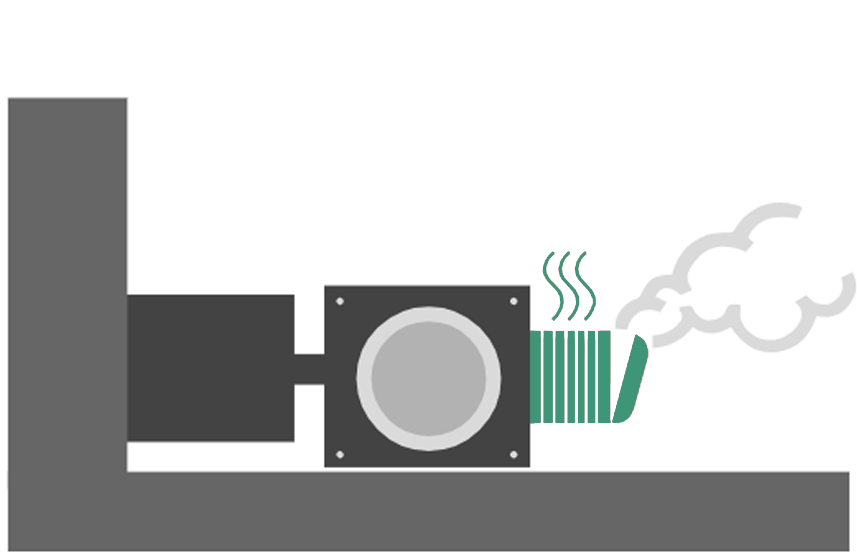

HAZARD: OVERLOAD

CONSEQUENCE: Potential consequences are shock, burns or fire caused by heat or arcing generated by an overloaded element of an electrical system, such as a motor, a VSD, a wire, etc.

EXAMPLE – RISK ORIGIN: Overheating of electrical components

EXAMPLE – HAZARDOUS EVENT: Electrical current or heat generating components overheat and cause a fire

HAZARD: LACK OF EQUIPOTENTIAL BONDING

CONSEQUENCE: Potential consequences are shock or electrocution; for example, when leakage of current passes through human body and fatality occurs due to improper earthing.

EXAMPLE – RISK ORIGIN: Person(s) in contact with parts which have become live under faulty conditions

EXAMPLE – HAZARDOUS EVENT: Electric shock due to indirect contact, e.g. due to faulty or inadequate insulation or lack of equipotential bonding

EXAMPLES OF UNINTENTIONAL HAZARDS

HAZARD: OVERSPEED

CONSEQUENCE: Potential for impact, crushing, being thrown, being run over, slipping, tripping, or falling. For example, this can happen from machinery overspeeding due to failure of speed regulators.

EXAMPLE – RISK ORIGIN: Failure pr malfunctioning of the control system

EXAMPLE – HAZARDOUS EVENT: Increase of travel speed (e.g encoder, motor or inverter failure

HAZARD: UNCONTROLLED SPEED

CONSEQUENCE: Potential for impact, crushing, being thrown, being run over, slipping, tripping, or falling. For example, this can happen from machinery exceeding the travel speed limits or overspeeding due to failure of speed regulators.

EXAMPLE – RISK ORIGIN: Approach of a moving element to a fixed part

EXAMPLE – HAZARDOUS EVENT: Uncontrolled movements, uncontrolled speeds.

HAZARD: MACHINERY OVERTRAVEL

CONSEQUENCE: Potential for impact, crushing, being thrown, being run over, slipping, tripping, or falling. For example, this can happen when machinery exceeds the end of travel limits due to a lack or failure of overtravel protection.

EXAMPLE – RISK ORIGIN: Approach of a moving element to a fixed part

EXAMPLE – HAZARDOUS EVENT: Overtravel or position error (e.g. encoder failure)

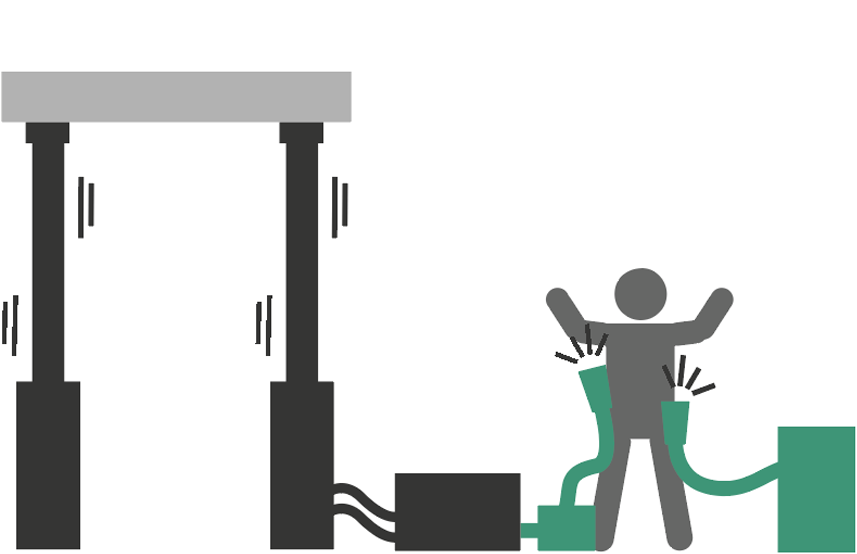

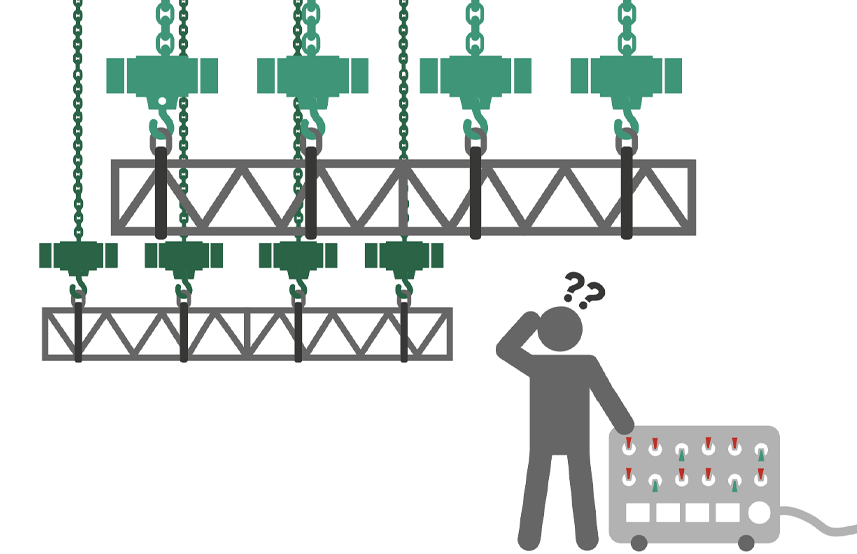

HAZARD: UNINTENTIONAL MOVEMENT

CONSEQUENCE: Potential consequences are impact, crushing or shearing caused by an unintentional start/stop or unintentional movement due to software failure, mistaken programming, poor control system design or failure of a mechanical element or safety-related device.

EXAMPLE – RISK ORIGIN: Potential consequences are impact, crushing or shearing caused by an unintentional start/stop or unintentional movement due to software failure, mistaken programming, poor control system design or failure of a mechanical element or safety-related device.

EXAMPLE – HAZARDOUS EVENT: Unintentional start-up, stop command is not carried out, e.g. wrong hoist starts up.

EXAMPLES OF THERMAL HAZARDS

HAZARD: FLAME

CONSEQUENCE: Potential consequences are fire, burns, injuries from radiated heat and scalds caused by short-circuits, overheated machinery elements that can cause flames or are located near combustible materials.

EXAMPLE – RISK ORIGIN: Shortcut between live parts

EXAMPLE – HAZARDOUS EVENT: Shortcut between live parts creates severe overheating with possible burns or fire.

HAZARD: OBJECT OR MATERIALS WITH A HIGH OR LOW TEMPERATURE

CONSEQUENCE: Potential consequences are burns, injuries from radiated heat, scalds and frostbite caused by direct contact with parts which can become hot or cold, such as hot brake resistors or cold metal parts of machinery.

EXAMPLE – RISK ORIGIN: Overheating of electrical components

EXAMPLE – HAZARDOUS EVENT: Potential consequences are burns, injuries from radiated heat, scalds and frostbite caused by direct contact with parts which can become hot or cold, such as hot brake resistors or cold metal parts of machinery.

EXAMPLES OF IMPROPER USE HAZARDS

HAZARD: IMPROPER OPERATION

CONSEQUENCE: Potential consequences of lifting or motion operations include being thrown, impacted, severed, crushed, falling from a height, and being drawn in. Examples of these consequences can occur when people are working in the hazard zone and an unauthorised or incompetent operator is carrying out lifting or motion operations without knowledge or awareness of the related risks.

EXAMPLE – RISK ORIGIN: Hazards due to improper operation

EXAMPLE – HAZARDOUS EVENT: Manufacturers intended uses of machinery are disregarded by the user.

HAZARD: IMPROPER START UP / USE

CONSEQUENCE: Potential consequences are being thrown, impact, severing, crushing, falling from height and drawing-in. Some examples of this can occur when people are working in the immediate vicinity of the hazard zone and the upper or lower machinery motion is activated.

EXAMPLE – RISK ORIGIN: Hazards due to improper operation

EXAMPLE – HAZARDOUS EVENT: Factors which can lead to damage are not recognised

HAZARD: UNAUTHORISED OPERATION

CONSEQUENCE: The potential consequences of unauthorised operations are many, including crushing, impact, falling, and being thrown. For example, when an operator is ill or absent, the machinery may be operated by an untrained or unqualified person.

EXAMPLE – RISK ORIGIN: Failure/unauthorised start-up/use

EXAMPLE – HAZARDOUS EVENT: If the operator is ill, an unauthorised person is allowed to operate the machinery.

EXAMPLES OF ERGONOMIC HAZARDS

HAZARD: DESIGN, LOCATION OR IDENTIFICATION OF CONTROL DEVICES

CONSEQUENCE: Potential consequences are being thrown, impact, severing, crushing, falling from height and drawing-in. Some examples of this can occur when control stations are not properly labelled and when operators have limited visibility of the hazard zone.

EXAMPLE – RISK ORIGIN: Inadequate design, location or identification of manual controls

EXAMPLE – HAZARDOUS EVENT: ESTOP or ENABLE stations are located too far from the movement/lifting area

HAZARD: DESIGN OR LOCATION OF INDICATORS AND VISUAL DISPLAY UNITS

CONSEQUENCE: Potential consequences include being thrown, struck, severed, crushed, falling from a height, and drawn in. Some examples of this can occur when control station direction switches are badly labelled, or when indicator light colours are misleading.

EXAMPLE – RISK ORIGIN: Inadequate design or location of indicators and visual display units

EXAMPLE – HAZARDOUS EVENT: Small or misleadingly colour-coded displays and switches cause reading errors

HAZARD: ACCESS

CONSEQUENCE: The potential consequences are crushing or impact, which can occur by being trapped between the machines moving parts or the load and a fixed structure, such as the wall or the floor. For example, people can be crushed by stage elevator platforms of the ulower machinery in motion.

EXAMPLE – RISK ORIGIN: Dangerous access to machinery

EXAMPLE – RISK ORIGIN: User interface location or control station has no direct line of sight or complete overview of the hazard zone

HAZARD: REPETITIVE ACTIVITY

CONSEQUENCE: The potential consequences are crushing or impact injuries, which can occur if the person subject to the intense repetitive activity is forced to bypass or circumvent safety guidelines, voiding the effects of the safety devices. For example, people can be crushed by a moving object if the dead man’s handle or foot pedal is bypassed or kept permanently engaged.

EXAMPLE – RISK ORIGIN: Unhealthy posture or excessive effort

EXAMPLE – HAZARDOUS EVENT: Excessive holding or actuating forces required

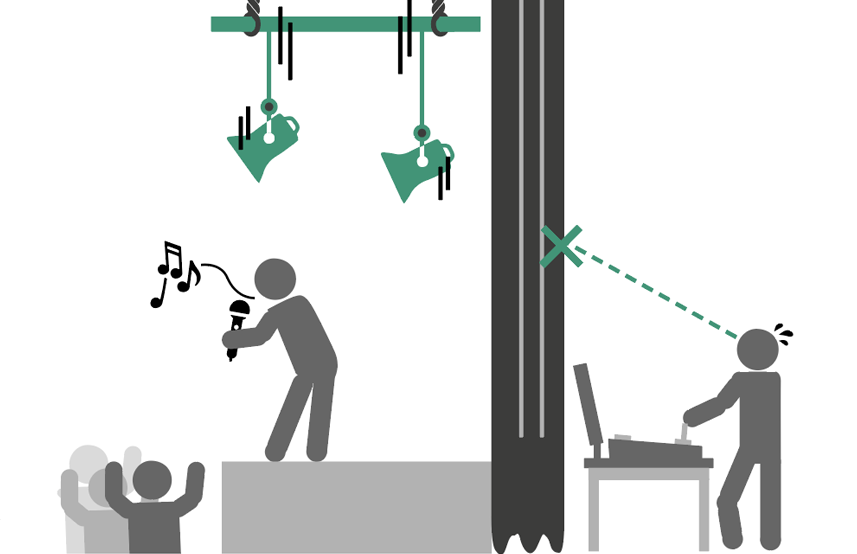

HAZARD: VISIBILITY

CONSEQUENCE: Potential consequences are being thrown, impact, severing, crushing, falling from height and drawing-in. Some examples of this can occur when control stations are located too far from the hazard zone or when operators have limited or no visibility of the hazard zone.

EXAMPLE – RISK ORIGIN: Inadequate design, location or identification of manual controls

EXAMPLE – HAZARDOUS EVENT: User interface location or control station is too far from the lifting area.